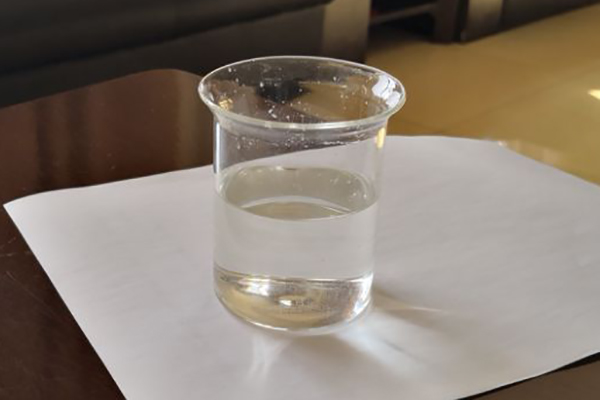

Sodium metabisulfite is also known as partial sodium sulfite, heavy sulfoxide, sodium metabisulfite, etc. The appearance is white or yellow crystalline powder or small crystals. It is acidic when dissolved in aqueous solution, and it can generate corresponding salts when contacted with strong acid. Sodium metabisulfite can be divided into technical grade sodium metabisulfite and food grade sodium metabisulfite.

Industrial grade sodium metabisulfite:

It can be used for leather treatment in leather making, making the leather soft and tough with the functions of waterproof, folding resistance and wear resistance.

Sodium metabisulfite used for printing and dyeing can be used as a deoxidizing agent for cotton cloth bleaching and as an auxiliary agent for cooking cotton cloth.

It is also used in the photographic industry as an ingredient for fixing agents, oilfield wastewater treatment, chromatographic analysis reagents and mine beneficiation agents.

Food grade sodium metabisulfite:

It can be used as bleaching agent in flour for making cakes, buns and other foods.

Used in the production of bread and biscuits and other foods to make it soft and taste better.

Adding it to fruit juice, candied fruit, canned food can prolong its shelf life, and it also has a sterilizing effect.

It has good antioxidant and fresh-keeping effects on seafood, fruits and vegetables.

The field of use of sodium metabisulfite is gradually increasing. Sodium metabisulfite can choose different production processes according to different usage needs. Its production processes mainly include the following two:

First, dry method

Mix soda ash and water according to a certain proportion, put them into the reactor after agglomeration, leave a certain gap between the blocks to input sulfur dioxide, and after the reaction is finished, take out the blocks and pulverize to obtain the finished product. The consumption of raw materials in this process is relatively large, and the purity is relatively low.

Second, wet method

Add soda ash to the raw material solution to react. After the suspension appears, input sulfur dioxide to form crystals, separate the crystals, and then dry to obtain the finished product. This process consumes less raw materials and the product is very pure.

◆ Export Business Department Ⅰ:Mr.Steven Sun

+86-15822712322

E-mail:steven@huizhongchem.com

◆ Export Business Department Ⅱ:Ms. Katherine Yang

+86-13752275385

E-mail:katherine@huizhongchem.com

◆ Factory add.:Nanpu Economic and Technological Development Zone,Tangshan

Office add.:A1-406,TEDA New Skline Mansion,No 12 Nanhai Road,TEDA Tianjin

![]()